Hangzhou Jinggong: Innovation driven development, leading the new future of high-end manufacturing

Hangzhou Jinggong Machinery Co., Ltd. and Zhejiang Jinggong Integrated Technology Co., Ltd. (referred to as “Jinggong Technology”), as benchmark enterprises in China’s high-end equipment manufacturing, have always focused on technological innovation and deeply cultivated the fields of carbon fiber, glass tempering equipment, and green manufacturing. With a full industry chain layout and breakthrough achievements, they continue to lead the high-quality development of the industry.

1、 Leading technology, breaking through the bottleneck problem

Jinggong Technology has been involved in the carbon fiber industry since 2013 and has now become a leader in the global carbon fiber equipment field. Its independently developed JCY300D gas electric hybrid heating pre oxidation furnace fills the domestic technological gap, improves energy efficiency by 30%, and has been awarded the title of “China’s first (set) equipment”. The high-performance carbon fiber production line with an annual output of 5000 tons released in 2025 will achieve a 35% increase in intelligence level and a 19.9% decrease in energy consumption per ton, helping domestic carbon fiber enter a new stage of low cost and high efficiency. In addition, Jinggong Technology and Dexen Technology have collaborated to develop graphene based carbon fibers, breaking the traditional petroleum preparation path and leading the world in thermal conductivity, providing lightweight solutions for fields such as aerospace and new energy vehicles.

2、 Green intelligent manufacturing, creating a benchmark for “zero carbon”

Jinggong Technology actively responds to the national “dual carbon” strategy and has built the first “zero carbon factory” in the construction industry in Zhejiang Province. Through rooftop photovoltaic power generation, electrification equipment, and digital management, the annual carbon reduction exceeds 5000 tons, achieving full lifecycle carbon neutrality and obtaining national certification. At the glass tempering equipment production base in Bengbu, photocatalytic waste gas treatment technology is adopted, with an environmental investment of 2.4 million yuan, promoting sustainable development of the industry through green processes.

3、 Full chain layout, empowering the global market

From raw silk equipment to composite application, Jinggong Technology has built a “three in one” carbon fiber full industry chain, undertaking more than 50 production lines, with a domestic market share of over 50%, and products exported to South Korea, Vietnam and other places. Its glass tempering equipment has an annual production capacity of 200 units, covering areas such as photovoltaics and building energy conservation, and helping customers enhance their competitiveness with efficient and intelligent production lines.

4、 Honor added, showcasing industry status

Jinggong Technology has won multiple awards such as the “Top Ten Textile Technologies in China” achievement and the first prize for scientific and technological progress. It has taken the lead in formulating national standards and its technical strength has been recognized by international authorities. で 2024, the company will establish a green manufacturing benchmark with the “zero carbon factory” certification, promoting the industry’s transition to low-carbon.

Hangzhou Jinggong takes “innovation without limits” as its core concept, continuously breaking through technological barriers and empowering global high-end manufacturing. In the future, the company will continue to deepen its “equipment+materials+applications” three in one strategy, work together with partners, inject surging power into China’s intelligent manufacturing, and jointly build a new future of green technology!

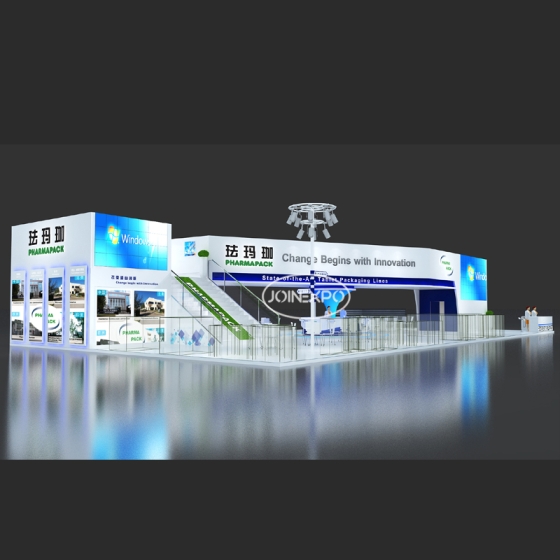

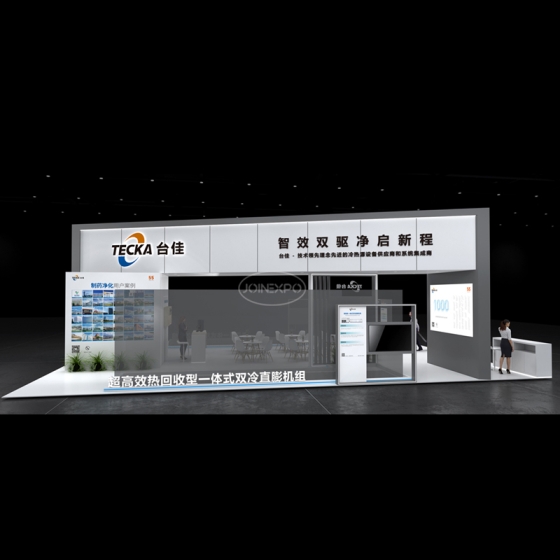

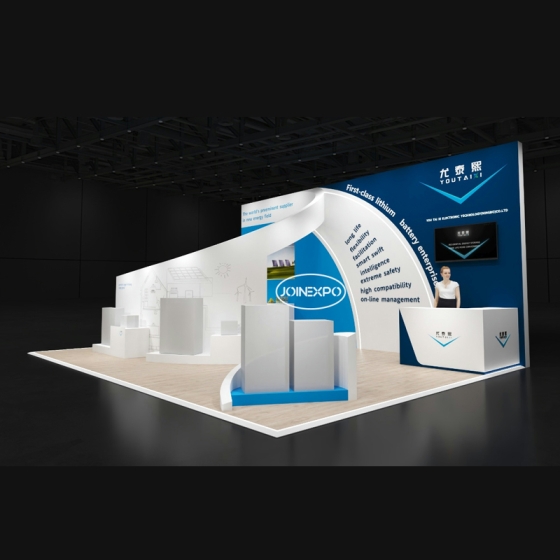

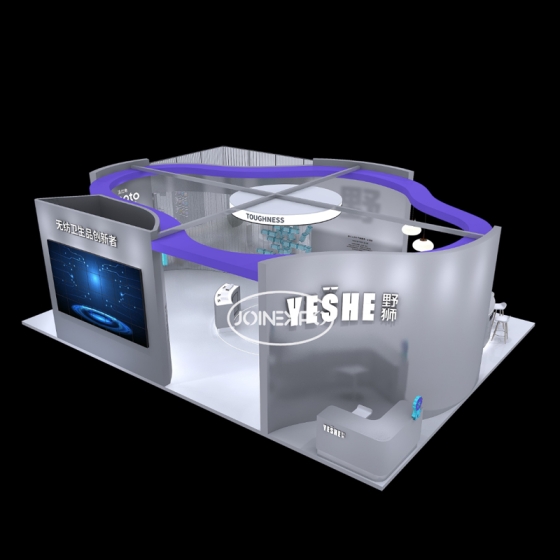

Joinexpo展示Construction Company

Joinexpo展示Construction Company